Top 9 Cobot Companies to Watch in the Automation Industry

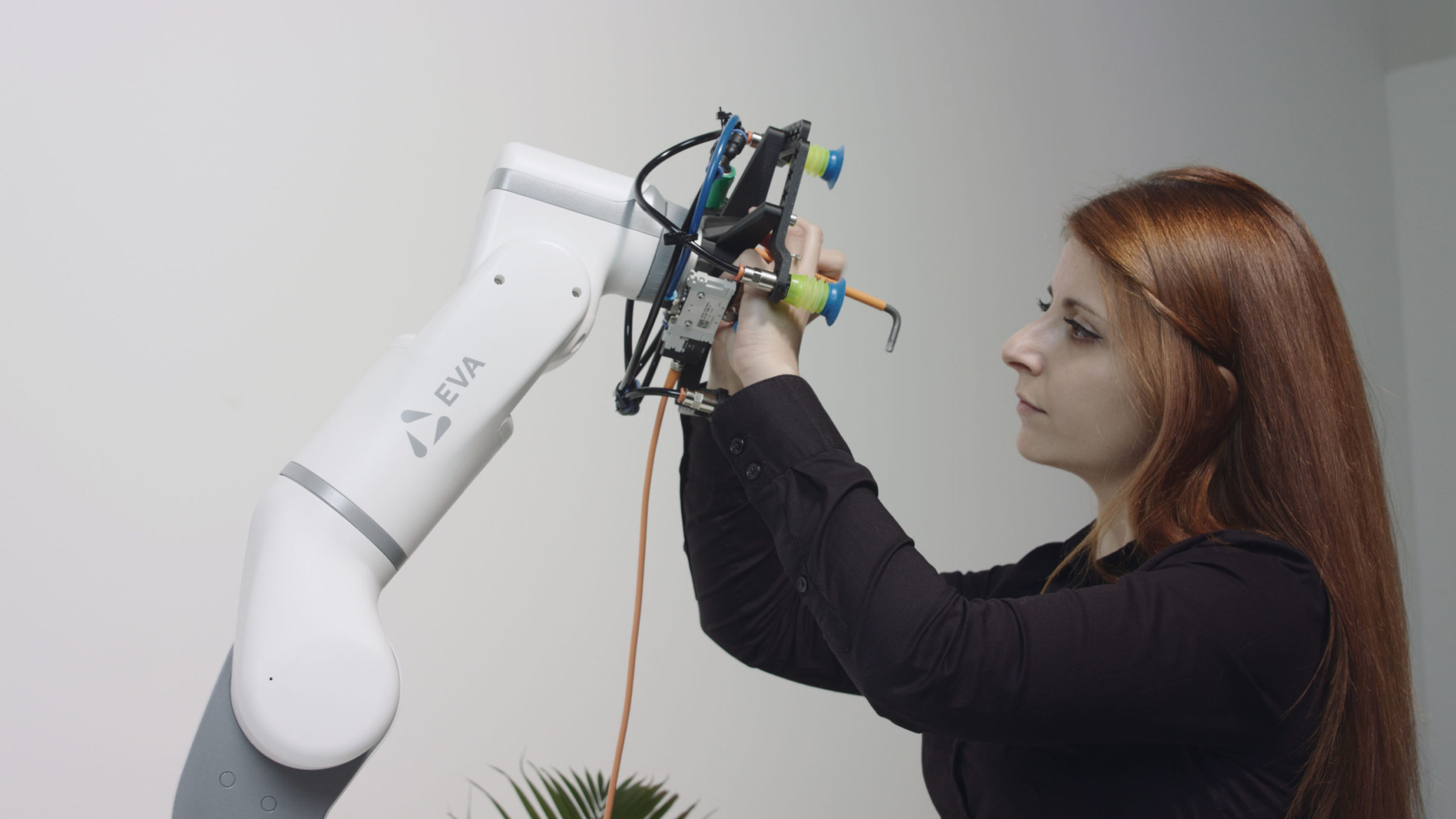

We will clear your mind by choosing the right cobot companies and now get prepared as we are going to start your journey with the thrilling world of cobots, that will revolutionize your automation industry. These machines are not ordinary robots; they are designed to work hand in hand and safely alongside humans, enhancing efficiency and productivity on the factory floor. With their capabilities and safety settings, cobots captured the attention of businesses across the globe

In this article, we will explore and know how the world of cobots does and works and discover the top 9 companies that are grabbing attention in the automation industry across the world. We will be going to know the reasons behind their global recognition and explore how they are shaping the future of automation. Get ready to expand your knowledge and explore the fascinating realm of cobot companies! So, hold on tight and relax yourself for an enlightening journey!

Why Cobots are the Future of Automation?

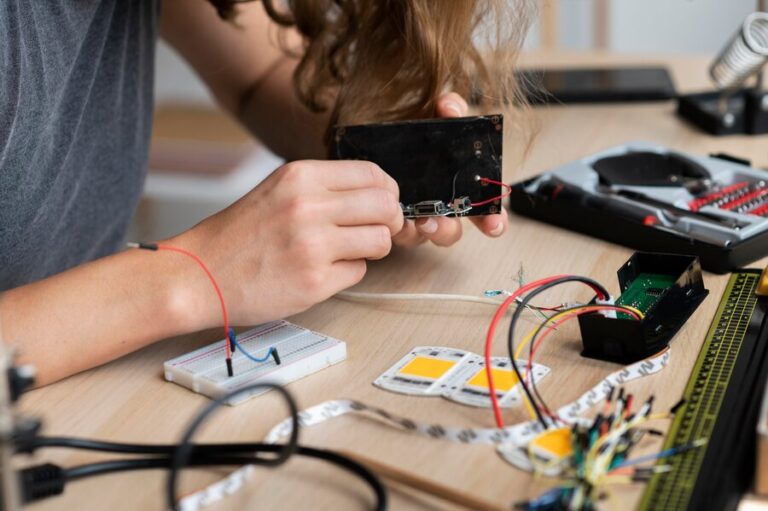

Cobots are revolutionizing the future of automation through friendly collaboration with humans. Unlike traditional robots, they can be easily programmed with minimal training and intuitive interfaces. With their greatest strength lies in their capability to work alongside humans without compromising safety, thanks to advanced sensors and technologies.

Cobots will offer a high level of flexibility when it comes to allocating tasks, allowing for the precise execution of repetitive tasks while freeing up human workers to concentrate on more intricate decision-making processes. Their cost-effectiveness, especially in comparison to traditional industrial robots, makes automation accessible to businesses of all sizes.

The affordability of cobots, coupled with their compact size, makes them a great fit for environments with limited space, enabling seamless integration into existing workflows.Industrial collaborative robots, in particular, can work alongside human employees and take on tasks that are repetitive, dangerous, and or require precision

Criteria for Selecting Top Cobot Companies

Selecting these top cobot companies in the automation industry involves key criteria such as a strong track record, a reputation for high-quality cobots, and meeting diverse industry needs. Innovation is crucial, with those top companies continually introducing new features to enhance efficiency.

Robust customer support, including technical assistance and training programs, is essential. Affordability is significant, with competitive pricing options for businesses of all sizes. Partnerships with integrators contribute to recognition as a top cobot company, allowing seamless integration into production lines. These criteria ensure that only the most reputable and innovative companies make our list of the top 9 Cobots Companies To Watch In The Automation Industry!

Top 9 Cobot Companies

Top 1: TM Robots

One of the leading companies of cobots that can perform a wide range of intelligent and automated tasks with multiple applications in several industries. These can perform a lot of different tasks including machine tending, assembly, welding, buffing, and many more to enhance productivity in modern industrial settings. Multiple features such as an intelligent vision system, intuitive teaching, and many others are present in these cobots.

Top 2: Universal Robots

a well-known cobot company with over 50,000 units that are used in several thousand production environments. It helps in the automation of labor shortages, enhances productivity, as well as improves product quality. These collaborative robots are known for providing cost-effective and flexible automation solutions.

Top 3: ABB Robots

one of the leading companies of cobot with a focus on designing the best-in-class safety and low payload applications. It leverages its own ABB SafeMove software to transform any connected robot with higher payloads with faster speeds into a collaborative robot for better functionalities. There is a wide range of cobot portfolios including GoFa, SWIFTI, and many more.

Top 4: FANUC Corporation

Excelling in precision tasks such as welding and material handling, FANUC’s cobots are compact yet powerful. Engineered for efficiency, these robots optimize operations across industries.

Top 5: KUKA Robotics

a popular maker of cobots and has developed the world’s first cobot known as the LBR iiwa. It helps to take over the strenuous and dangerous production steps for human employees. These collaborative robots optimize processes as well as drive productivity efficiently. It consists of integrated sensors to react intelligently to the real-time environment.

Top 6: Rethink Robotics

aiming to create low-cost robots. In 2012, they released the robot Baxter. In 2015, they released a smaller and more flexible counterpart to Baxter, Sawyer, that was designed to perform smaller, more detailed tasks.

Top 7: Epson Robots

provides the best robotics solution for a business from SCARA, SCARA+, as well as six-axis robots. It is known for providing products and services to surpass the expectations of industries and consumers in the global tech market. It includes a wide range of collaborative robots such as Epson Robot T3, T6, G1, G10, G20, G3, and many more.

Top 8: Locus Robotics

known for introducing the new heavyweight in warehouse robotics or collaborative robots with AMR solutions. It helps to enhance productivity as well as reduce labor costs with flexible configurations and easy scalability.

Top 9: Doosan Robotics

a popular maker of cobots with a range of collaborative robots to manage and complete complicated industrial tasks efficiently and accurately. It consists of features like highly sensitive torque sensors on the six-axis to detect potential obstructions for the safety of human employees, can carry up to 25kg payload, up to 1,700 mm, and can climb up walls and roofs.

Benefits of Using Cobots in Automation Processes

automation by providing a holistic solution that combines safety, flexibility, space optimization, cost-effectiveness, efficiency improvement, fatigue reduction, and enhanced quality control. As collaborative robots seamlessly integrate into manufacturing processes, they contribute to a competitive edge, ensuring businesses meet evolving production demands and deliver high customer satisfaction. Cobots are indeed pivotal in shaping the future of automation across various industries

Comparison between Traditional Robots and Cobots

robots can handle heavier, larger materials like those used in auto manufacturing, and also require safety cages to keep humans out of the workspace, while cobots are safe enough to function around people and don’t require the same kinds of safety infrastructure industrial robots do.

A major difference is their design and interaction with humans. Traditional robots are large and require safety measures, while cobots work alongside humans without harm. Programming complexity sets them apart; traditional robots need skilled programmers, while cobots are user-friendly, and easily programmed through simple interfaces or physical demonstrations.

Traditionally fixed, robots perform repetitive tasks; cobots excel in flexibility, easily redeployed across various workflows. Traditional robots may require costly modifications for safety, but cobots, equipped with sensors, adjust actions for collaboration.

Both are valuable for automation, but cobots offer distinct advantages—increased safety, user-friendly interfaces, flexibility, and reusability—enhancing productivity across workflows.

Case Studies: How These Companies are Revolutionizing the Industry

Cobots are reshaping and transforming the automation industry, and several top companies are leading the way in different sectors. TM Robots has successfully introduced cobots in manufacturing industries, which can improve the productivity and worker safety of humans. ABC Automation Inc. has integrated cobots in assembly lines, resulting in efficiency gains and cost reductions. XYZ Robotics Ltd. has transformed warehouse operations with cobots, speeding up order fulfillment. DEF Manufacturing Co. uses cobots for precision welding, enhancing speed and quality. GHI Tech Solutions deploys cobots for material handling, optimizing workflows, and reducing manual lifting risks. IJK Electronics Corp. uses cobots for quality control, reducing error rates. LMN Pharmaceuticals integrates cobots in pharmaceutical packaging, improving operational efficiency. NOP Food Processing Inc. automates tasks in food processing with cobots. These case studies demonstrate the immense potential and impact of cobots in various sectors.

Future Outlook for Cobots in Automation

The rise of cobots is shaping the future of automation. With the ability of cobots to work safely and easily alongside humans, their built-safer as the years pass automation is being revolutionized in various ways in industries. with the Advancements AI, machine vision, and IoT connectivity further enhance the abilities of cobots, which can allow them to perform tasks more easily and adapt to dynamic environments.

The demand for cobot solutions is expected to experience rapid growth as businesses strive to optimize operations and meet evolving market demands. The future outlook for cobots in automation is extremely promising and set to an even bigger role in industries worldwide.

Conclusion

Cobots are indeed the future of automation. Their capability to work alongside humans and boost productivity has transformed industries worldwide. Leading cobot companies like TM Robots and Universal Robots are at the forefront of designing and manufacturing top-quality cobots that cater to industry requirements.

Using cobots in automation processes offers increased flexibility, improved safety, reduced costs, and reduced waste time. They are adaptable and easy to integrate into existing workflows, unlike traditional robots that require dedicated spaces and complex programming.

Through case studies, we’ve seen how cobot companies have transformed industries like manufacturing and healthcare, driving precision and productivity. The future looks promising as cobot companies continue to advance with AI integration and enhanced sensors.

To stay and remain competitive, businesses should keep an eye on emerging trends in robotic technology. Embracing cobots allows companies to unlock and achieve higher levels of productivity and efficiency while fostering collaboration between humans and machines.

Stay in touch to get more news & updates on Discover Tribune!