What Is the Difference between Development Board and Evaluation Board?

If you are into electronics and printed circuit board assembly, you must have come across development boards and evaluation boards. These two boards are indeed the top players in the world of electronics having important roles in different applications.

But wait, are not these two different names of the same thing? The simple answer is no! Both these boards have different roles. While development boards foster innovation and creativity, evaluation boards help find the capabilities of electronic components before introducing them into the real world.

So let’s move forward and explore the functions and applications of each of these boards and the difference between them.

What Are Evaluation Boards?

As the name suggests, an evaluation board helps in the evaluation of various components. These boards are crafted meticulously to assess the performance, capabilities, and features of specific integrated circuits. These boards can be integral in various stages of printed circuit board assembly, as they allow for testing and debugging before the full production phase.

Electronic manufacturing companies, like Xilinx, Analog, and Toshiba, produce these evaluation boards to facilitate a deeper understanding of their products.

EMS manufacturing also benefits significantly from evaluation boards. As part of EMS manufacturing, these boards help in designing, testing, and building electronic components and assemblies for original equipment manufacturers (OEMs).

They provide an efficient way to analyze how a component will perform within a system, thus enabling manufacturers to make necessary adjustments before mass production. The Blind vias enable engineers to manufacture compact connections between different PCB layers.

Key Features of Evaluation Boards

Evaluation boards are also known as demo boards. Most engineers prefer these boards for assessing the performance of some components. Printed circuit board assembly helps incorporate circuitry components into the evaluation board.

The following section covers the key features of evaluation boards.

- Product Development: Electronic manufacturing companies design these boards to help engineers test the performance and compatibility of specific components before integrating them into larger systems.

- Power Management: The evaluation board also has power regulation circuitry that helps provide the required voltage and current levels to the evaluating component.

- Testing Points: Some points on the evaluation board are equipped with testing points or headers, thus allowing the manufacturers to take readings and measure signals.

- Evaluation Software: Most demo boards come with evaluation software that enables the manufacturers to gather data and also visualize the behavior of components in real-time.

- Connectivity Options: The standard communication protocols are used in evaluation boards like USB, I2C, UART, and SPI. These connectors allow manufacturers to interface with the components.

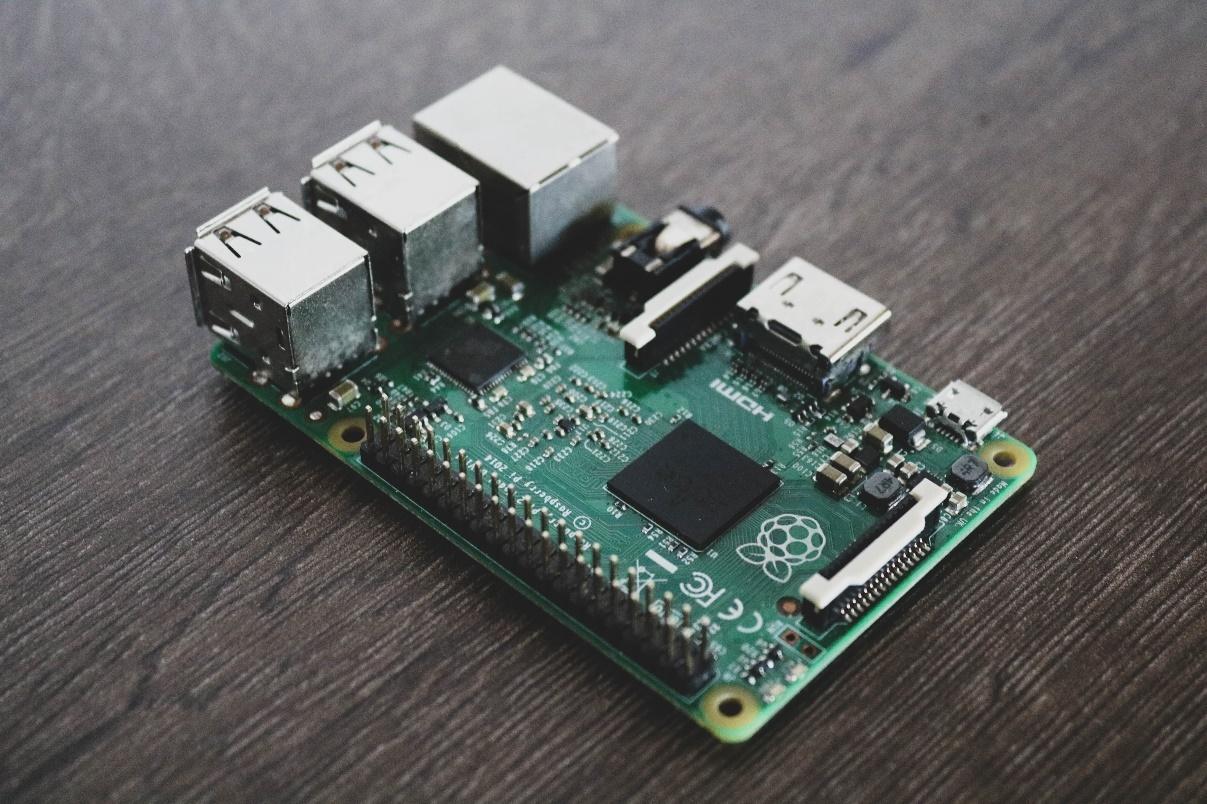

What Are Development Boards?

Since evaluation boards are used for development purposes as well, they are often confused with development boards.

Produced by electronic manufacturing companies, development boards contain a microprocessor and the minimal support logic needed for an electronic engineer to become familiar with the microprocessor on the board and learn how to program it.

Development boards also have significant applications in EMS manufacturing. EMS providers offer comprehensive services ranging from design, assembly, and testing to distribution of electronic components and assemblies.

Blind vias are incorporated strategically into the developments board design to enable a secure connection between various PCB layers. Development boards allow innovation as they enable users to explore various functionalities, thus helping in the creation of newer electronic systems and applications.

Key Features of Development Boards

Development boards are versatile and used by people of diverse fields to experiment, explore, and bring innovation. They have a couple of key features that are important in facilitating printed circuit board assembly, the designing, and the prototyping process. Let us shed some light on its key features:

- Connectivity Options: Standard communication interfaces are used, like UART, USB, I2C, SPI, etc. This helps the development boards connect smoothly to other devices.

- Memory: Development boards come with different types of memory options. The common ones are Random-access memory (RAM) and flash memory for program storage.

- Power Regulation: Power regulation circuitry is also incorporated in dev boards for stable voltage supply to the microcontroller and its various other components.

- Microcontroller: Dev boards are equipped with central processing units. It is like the brain of the whole system. In most cases, a microcontroller is that processing unit.

- Integrated Components: The built-in components in dev boards include buttons, sensors, display interfaces, LEDs, etc. Blind vias incorporation ensures they are of high quality. These components enable quick experimentation and prototyping.

Development Boards Vs. Evaluation Boards – The Difference

Development and evaluation boards are often confused as the same, but they are two different types of tools being used in electronics. You can find a top electronic manufacturing company in the US providing these boards. With EMS manufacturing, it can be ensured that these boards meet the highest standards of functionality and quality.

While development boards have a broad scope, including memory, interfaces, etc., eval boards are typically designed around a specific component. The careful placement of blind vias ensures strong connectivity between different boards.

Dev boards include software development tools that encourage experimentation and coding. On the other hand, eval boards feature evaluation software allowing manufacturers to gather data and configure settings.

While dev boards are beneficial in validating and testing new concepts and ideas, evaluation boards help in the in-depth testing of specific components to ensure they meet the expectations before integration. Dev board engineers prefer the incorporation of blind vias to enhance user experience.

Evaluation boards are almost always pre-designed, considering specific components only. However, dev boards offer custom areas for components. The latter is more flexible.

Both these boards are important in the product development cycle, helping in the creation of strong and efficient electronic systems, particularly by featuring blind vias.

Final Words

Development and evaluation boards both serve as important tools in the world of electronics, each having its unique purpose. Development boards allow innovation and serve as a creative toolbox, while evaluation boards help in the testing and validation of electronic components. Nonetheless, both these boards incorporate blind vias to improve overall performance.

It is essential to understand the differences between them to be better able to use them for innovations and leverage their strength to bring more success to the projects. A better understanding can definitely lead to a well-rounded approach in the field of electronic design and development. Reach out to rigid flex board electronic manufacturing company for further guidance.

Stay tuned for more news & updates on Discover Tribune!